Insulation nail

Classification and Application of Thermal Insulation Nails

Insulation nails are widely used in the construction and industrial sectors. They are mainly used to fix insulation materials such as rock wool, glass wool, and ceramic wool, aiming to improve energy utilization in buildings and industries. Insulation nails are commonly applied in insulation systems for exterior walls, roofs, floors, pipes, and equipment, fastening insulation materials in various positions to the target base materials.

In the selection of products to determine the required size, in accordance with the relevant standards to select, and view the relevant test report; To check whether the enterprise has the relevant production qualifications and certifications, which is an important guarantee for the production standards and product quality of the enterprise.

Then, through a comprehensive understanding of the credibility and reputation of the enterprise, choose the enterprise with high market recognition.

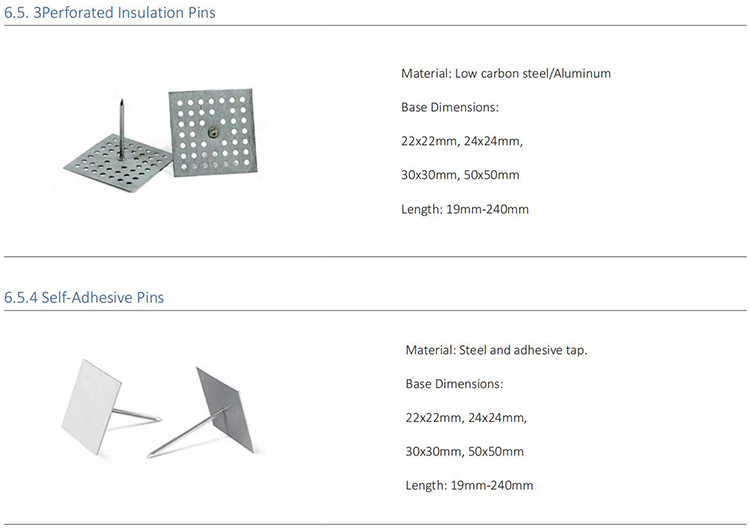

The three most common types of insulation pins are the capacitive insulation pins that require welding, the self-adhesive insulation pins for insulation, and the self-adhesive insulation pins with multiple perforations.

I. Advantages of Common Insulation Nails

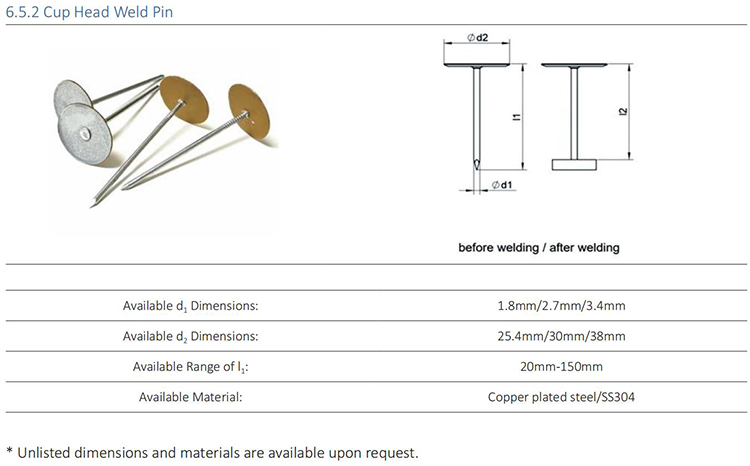

1. Capacitor insulation nails are heat resistant: They can be used in high-temperature environments. Firmness: They can stably fix insulation materials. Lightweight: The insulation nails are small in size, avoiding damage to the base material.

2. Self-adhesive insulation nails are easy to install: They can be directly pasted onto the base material without welding. Protect the base material: No welding is required, causing less damage to the base material. Wide application: They can be used on various base materials.

3. Perforated self-adhesive insulation nails are firmly fixed: They are specially designed to penetrate thick insulation layers to enhance stability. Various specifications: Multiple sizes are available to adapt to insulation layers of different thicknesses. Wide application: They are suitable for industrial and construction environments that require solid insulation support.

II. Installation Guide for Common Insulation Nails

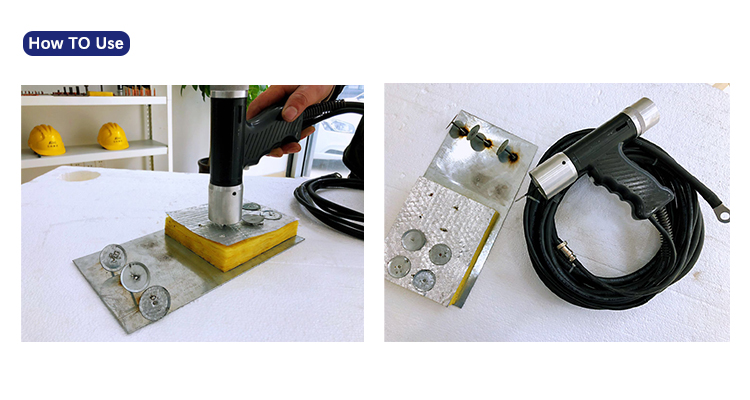

1. Installation Guide for Capacitor Insulation Nails: First, place the insulation material properly. Then, install the capacitor insulation nail into the insulation nail welding gun, align it with the position to be fixed, and perform capacitor welding.

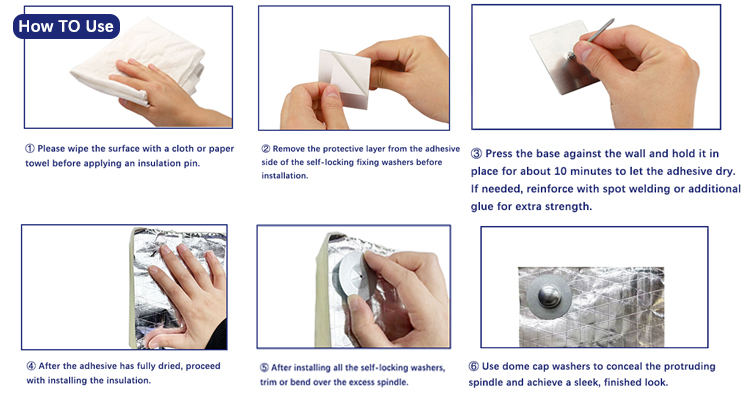

2. Installation Guide for Self-adhesive Insulation Nails: First, clean the surface of the base material thoroughly. Then, peel off the release paper of the self-adhesive insulation nail and stick it to the designated position on the base material. After that, fix the insulation material in place and press down the nail cap to secure the insulation material.

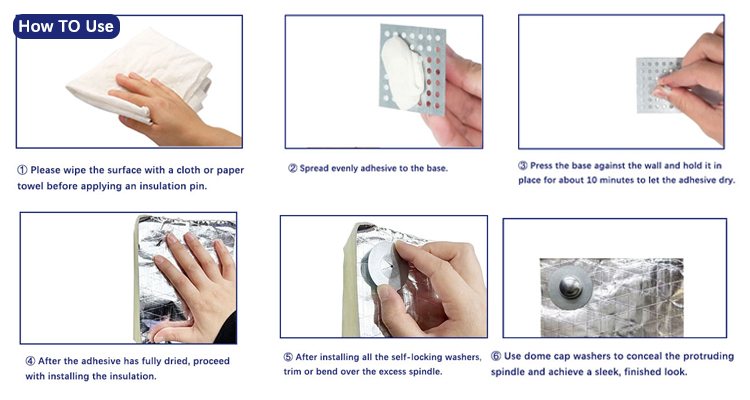

3. Installation Guide for Perforated Self-Adhesive Insulation Nails: First, clean the base material thoroughly. Then, apply the adhesive to the surface of the perforated insulation nail. Align it with the base material and stick it firmly. Next, fix the insulation material in place and fasten it by pressing down the nail cap.

When choosing insulation nails, users should not only consider the product type, performance, installation convenience, and cost factors but also the product size. This data sheet will provide detailed information on these aspects to help users select the insulation nail product with the most suitable size for their application. For data not marked in the table, customized products can be made according to size and material requirements.

In short, the selection of insulation nails needs to consider multiple factors, such as product type, performance, installation convenience, and size. When choosing products, the most suitable insulation nail products and enterprises should be selected based on specific insulation needs and scenarios.

Our company has comprehensive relevant certification certificates, and all products have testing reports. We have a very good reputation in the industry and have an absolute advantage. Putting customer needs at the center and emphasizing customer experience.