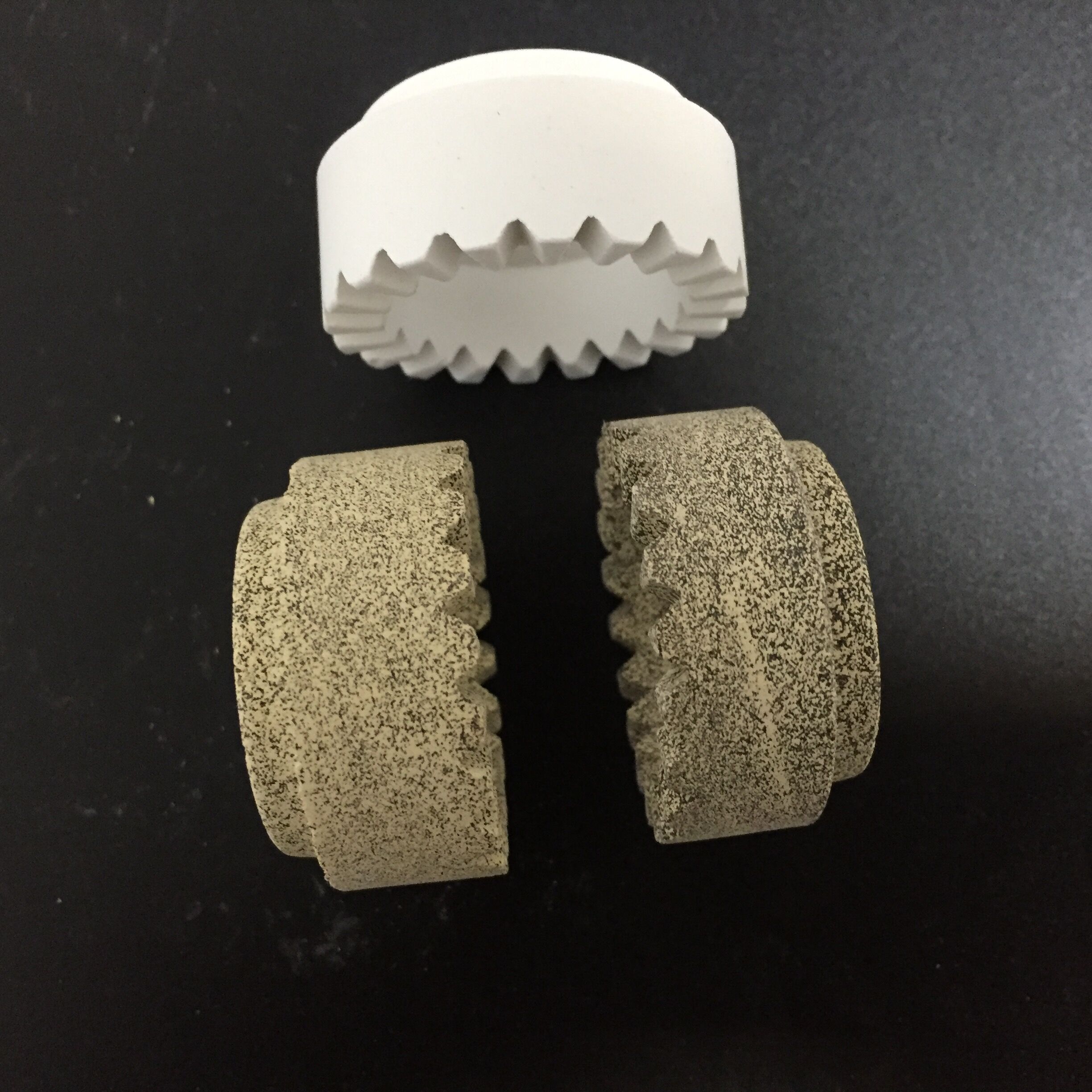

PRODUCT

Ceramic Ferrules for Stud Welding

Ceramic Ferrules are essential part of the standard shear connectors (shear studs) drawn arc stud welding process. In the process, the shear connector will insert into the center hole of the ceramic ferrule, the ceramic ferrule will be pressed on the welding surface by ceramic ferrule holder by the force of spring device inside the welding gun. The ceramic ferrule is used for one weld only and is removed once the molten metal has solidified.

Used for multiple purposes in stud welding. First, the ferrule helps to shield the arc from the operator. Second, it minimizes the atmosphere that the flux must purge. Third, the ferrule forms the molten metal into the fillet. Finally, the fillet vents allow weld gases to escape.

Ferrules are disposable items. As disposable items they are mass manufactured quickly and inexpensively. Ferrules are cast in a mold out of a low-grade moldable ceramic. They are taken out of the mold and are dried. Because of this manufacturing method, ferrule tolerances can be greater than machining or other manufacturing processes. Therefore, it is not recommended to fixture off a ferrule when exact location is required.

It has following functions:

Protection of the weld pool by creation of metal vapor in the burning chamber at sufficient current intensity, concentration and stabilization of the arc, thus reducing arc blow molding of the displaced weld pool to a weld collar and supporting of the weld pool. Furthermore, it shields the operator from both arc and spatter.

These standard ceramic ferrules are according to ISO 13918: 2008 Type UF, for shear connector welded to steel member in PA position.

Technical Data Sheet:

Ceramic Ferrule for Weld Studs Project Cases: