Welding Machine Knowledge

Efficient and Stable - IKSB-1250 Insulation Nail Welding Machine

The stable installation of insulation materials is the core to ensure long-term safe operation in heating, ventilation, and air conditioning (HVAC) systems and fire insulation engineering. The IKSB-1250 capacitive insulation nail welding machine launched by IKING has become the preferred equipment in the field of insulation nail welding due to its efficient welding performance, intelligent control, and industry-leading safety design.

The following are the basic parameters of IKSB-1250

|

Model |

IKSB-1250 |

|

Applicable nail specifications |

diameter 1-5mm (can weld 2mm and 3mm insulation nails) |

|

Base material requirement |

Steel thickness ≥ 0.3mm |

|

Welding speed |

up to 30 pieces per minute (3mm nails) |

|

Energy output |

Maximum output energy 1250J |

|

Input voltage |

single-phase 220V/50-60Hz or 110V/60Hz |

|

Allowable voltage fluctuation range |

± 10% |

|

Charging time |

3 seconds |

Application scenarios

1. HVAC field

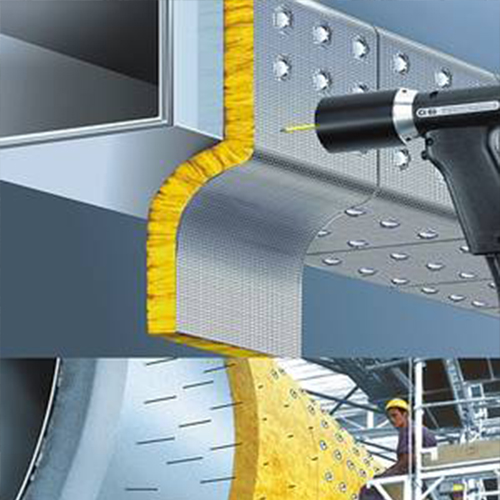

Used for welding disc-shaped (cup-shaped) insulation nails on central air conditioning ventilation ducts, replacing the traditional complex operation process of "welding nails → installing insulation cotton → installing buckles → trimming". The insulation pad can be directly fixed to the substrate through one-step welding, simplifying the construction steps and improving efficiency.

Suitable for welding insulation nails on the surface of insulation cotton for equipment, ensuring stable adhesion of insulation materials and preventing detachment due to vibration or temperature changes.

2. Industrial fire prevention field

Used in high-temperature scenarios such as thermal power plants, incinerators, chemical plants, and industrial furnaces in the petrochemical industry, special high-temperature resistant nails and buckles are welded to fix refractory insulation materials to the surface of steel structures, protecting them from high temperatures (up to 1250 ° C) and corrosion.

Optimize the installation of fire-resistant insulation materials, by welding specific insulation nails and clips, quickly and reliably fix the fireproof layer, and resist the damage of extreme temperature environments to steel structures.

Why choose IKSB-1250 insulation nail welding machine?

1. Suitable for fixed insulation and fireproof materials in various scenarios:

The insulation nail welding machine is designed for fast welding of insulation nails, used to fix insulation or fireproof materials. Suitable for scenarios such as central air conditioning ventilation ducts and industrial furnaces, ensuring that the insulation layer is firmly attached and preventing detachment and displacement.

2. Suitable for thin plate materials:

Energy storage welding technology allows for instantaneous discharge with almost no thermal impact, avoiding substrate deformation.

3. Complete in one step

By using the permanent magnet adsorption device at the head of the welding gun, the insulation layer can be directly penetrated and the substrate can be welded, significantly simplifying the process.

4. High temperature resistance

The welded insulation nails can withstand high temperatures up to 1250 ° C for structural protection, ensuring the thermal insulation and corrosion resistance of steel in high-temperature environments, and complying with fire insulation standards.

5. Security

Adopting fully digital control and strong weak current isolation design, with strong anti-interference ability; Equipped with overheat protection and misoperation prevention functions to enhance equipment reliability. The specialized welding gun is lightweight and suitable for long-term operations.

In summary, IKSB-1250 has become an ideal tool for HVAC engineering and industrial fire prevention due to its high-precision digital control, efficient energy output, and wide industry adaptability. Its design balances safety, durability, and ease of operation, making it particularly suitable for scenarios that require quick fixation of insulation or refractory materials. It is a reliable choice for improving construction efficiency and quality.