PRODUCT

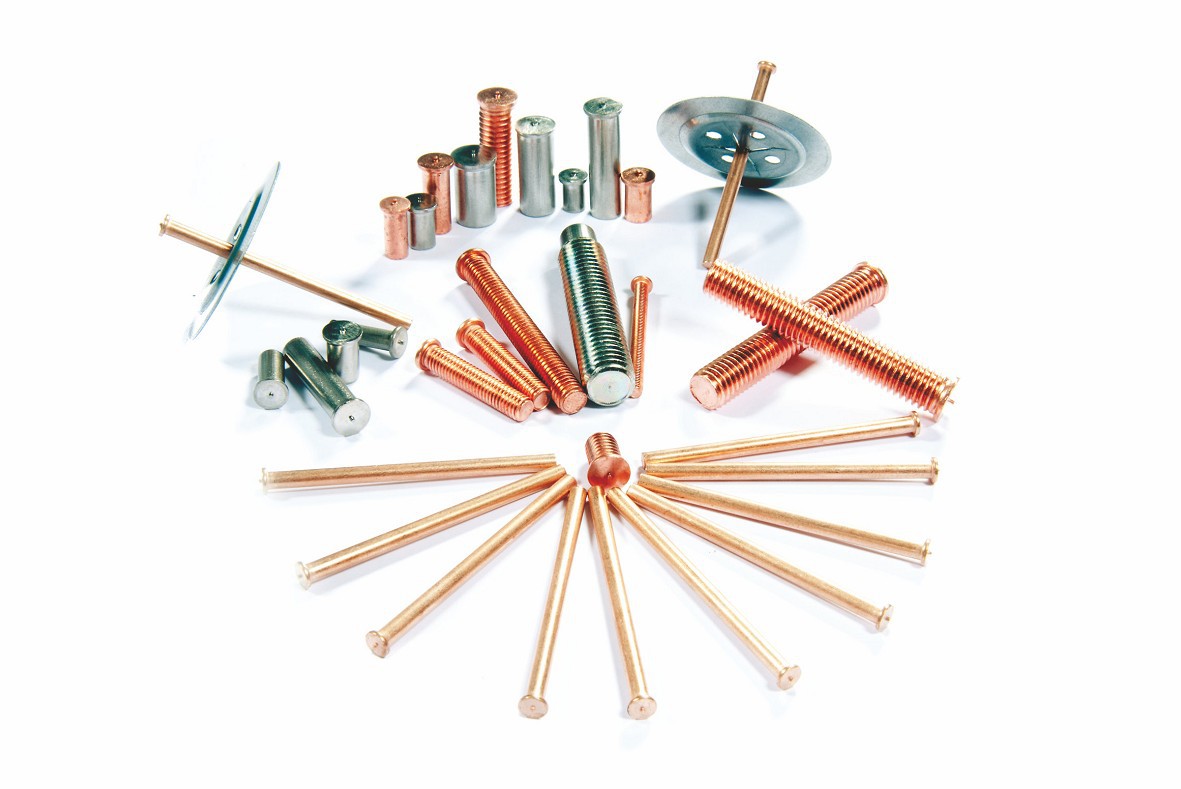

CD Capacitor Discharge studs

Our range of CD weld studs includes mild steel and stainless steel studs, pure aluminium and aluminium alloy studs, and lead-free brass studs. The materials we use are suitable for important relevant EN and ISO industry standards; for example, our aluminium studs are EN 573-3 compliant and our stainless steel CD studs comply to EN ISO 3506-3 (see our specification section below for the full list, as well as a downloadable CD stud catalogue). Many of our CD weld studs are available in threaded, unthreaded, and internally threaded forms, making them suitable for diverse applications.

Capacitor Discharge (CD) Stud Welding is also a semi-automatic arc welding process. However, with CD welding small diameter fasteners are end welded to extremely thin guage parent metal. The CD process operates on the principle of capacitor stored energy which is instantaneously discharged by the equipment system through a special weld “timing” tip. Since the entire weld cycle is completed in several milliseconds, welds can be made to thin sheet without pronounced distortion, burn-through or discoloration. CD welding permits stud welding of dissimilar metals.

Technical Data

CD Capacitor Discharge Studs Welding Process