PRODUCT

Short Cycle Welding Stud

Parent material with a thickness greater than 1.7mm (for thinner materials CD stud welding is the best choice, whereas for materials of 2mm and above DA may be the better process).

Three phase power source with 380~415-volt power supply.

Consider using shrouding gas for improved weld fillet formation and spatter reduction.

What is Short Cycle Stud Welding?

Short cycle stud welding is a quicker form of the drawn arc stud welding process for attaching metal studs and other fasteners to metal sheets. It only takes from 10 up to 100 milliseconds to attach the stud to the parent sheet using this method. CD weld studs can be used but, unlike CD stud welding, this process is suitable to use on slightly thicker sheet metals that are uneven or have imperfections. By bringing together elements of the DA and CD processes, Short Cycle proves to be a very effective method for applications where the parent material is thinner than what DA stud welding can tolerate, but you don’t require the full DA process to still get great results.

Short cycle is similar to drawn arc stud welding in many respects, as it requires three-phase power and a 415-volt power supply. However, this process is much faster and does not use a ferrule. Plus, the equipment and studs you can use for SC are much cheaper than those for DA. On the other hand, it can’t use weld studs as large as those used in Drawn Arc and is suited to thinner parent materials, so choosing SC stud welding really depends upon your setup!

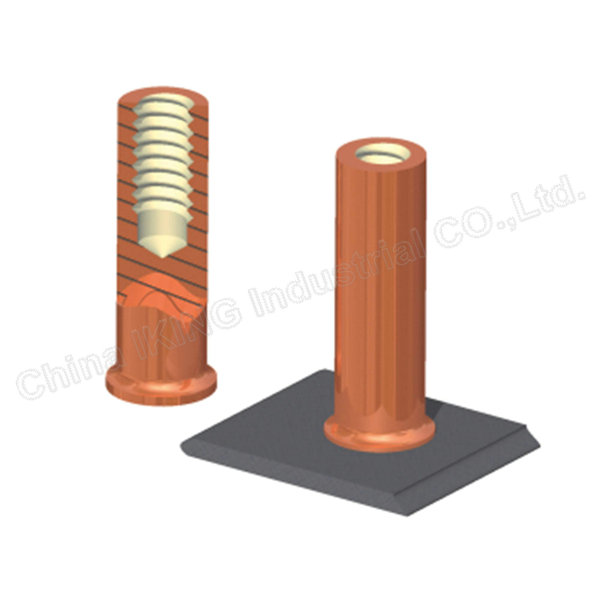

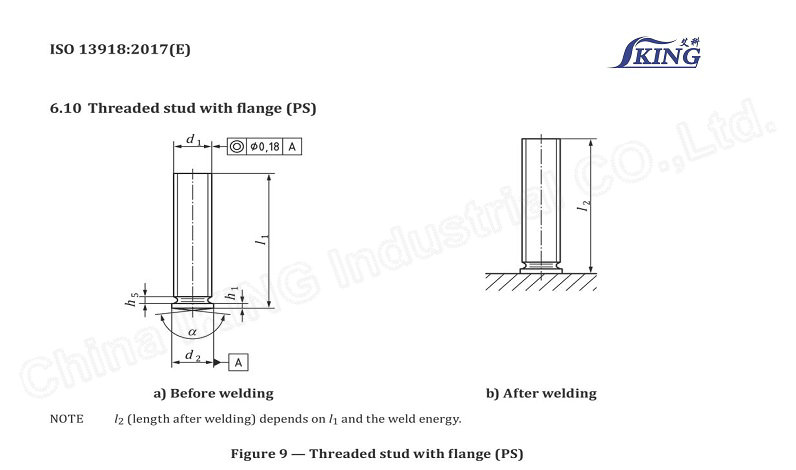

Short Cycle Stud

How Short Cycle Stud Welding Works