PRODUCT

IKING Carbon Steel Threaded Welding Stud for Sheet Metal Industry

Our Carbon Steel Threaded Stud is designed for arc stud welding using arc welders or a welding machine, providing a fast, reliable, and high-strength threaded studs connection. Made from high-quality carbon steel, it delivers exceptional tensile strength with welds stronger than the stud itself.

Material: Premium Carbon Steel

Surface Finish: Plain, copper plated, zinc plated etc.

Performance: Minimal thermal deformation, ensuring stable welding on thin steel or sheet metal.

Product Introduction

This carbon steel threaded stud is specially designed for arc stud welding using arc welders or a welding machine. It can be quickly welded to the surface of a metal base material to form a high-strength threaded connection point. As a high-efficiency threaded stud, it is widely used in the fields of steel structures and sheet metal fabrication.

Product Advantages

1. Ultra-Stable Welding Strength

Made of premium carbon steel, this threaded stud forms a metallurgical-grade fusion layer when welded with arc welders or a welding machine, ensuring high tensile strength. The weld strength surpasses that of the stud itself, making it resistant to loosening even under vibration or impact conditions.

2. Minimally Pleasing Thermal Deformation

When paired with a welding machine, welding torch, and ceramic ring (optional), the process completes quickly—saving assembly time. Ideal for thinner profiled steel sheets or sheet metal parts, the carbon steel stud provides reliable performance with minimal thermal deformation.

3. Full-Scene Adaptability

Thread Specifications: Multiple thread sizes available (customizable).

Surface Treatment: Copper plating or zinc plating, meeting green environmental standards and suitable for humid or corrosive environments.

Welding Machine Compatibility: Fully compatible with arc welders and other welding machines used in stud welding applications.

Product Parameters

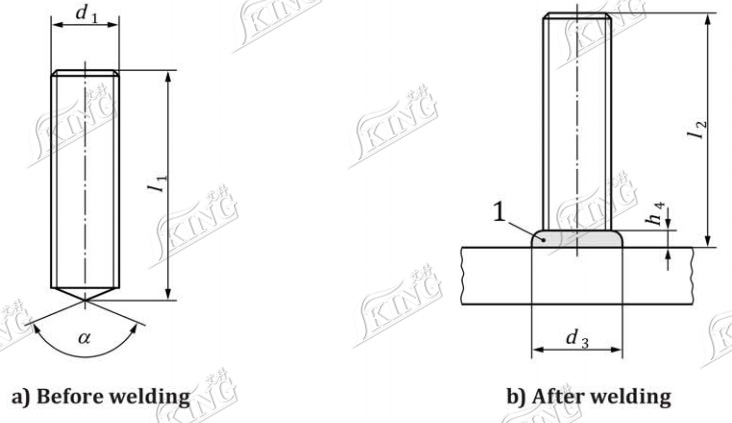

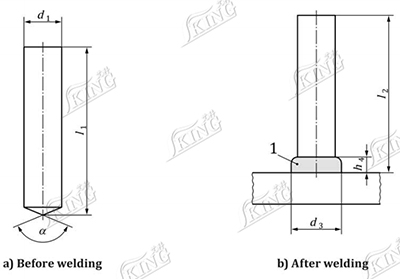

1.Fully-threaded stud (FD)

|

d1 |

M6 |

M8 |

M10 |

M12 |

M16 |

M20 |

|

d3ᵇ |

8.5 |

11 |

13 |

16 |

21 |

26 |

|

h4ᵇ |

4 |

4 |

4 |

5 |

7 |

7 |

|

α ± 7° |

140° |

|||||

|

l1 ± 1ᵃ |

l2 + 2.1 |

l2 + 2.2 |

l2 + 2.3 |

l2 + 2.8 |

l2 + 3.5 |

l2 + 3.8 |

|

l2 |

15–100 |

15–100 |

15–100 |

25–100 |

30–100 |

40–100 |

|

a Length l1 applies to angle 140°only(without tolerance). |

||||||

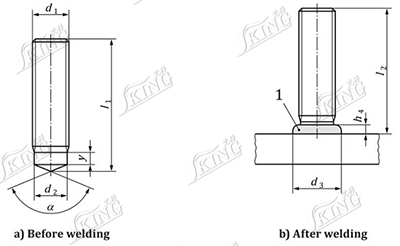

2. Virtually fully-threaded stud (MD)

|

d1 |

M6 |

M8 |

M10 |

M12 |

M16 |

|

d2 ± 0.1 |

5.35 |

7.19 |

9.03 |

10.86 |

14.6 |

|

d3ᵇ |

9 |

9.9 |

12.5 |

14.5 |

17.8 |

|

y |

5.5 |

6 |

6.5 |

7.5 |

11 |

|

h4ᵇ |

3.5 |

3 |

3.4 |

4.2 |

5.8 |

|

α ± 7° |

140° |

||||

|

l1 ± 1ᵃ |

l2 + 2.1 |

l2 + 2.2 |

l2 + 2.3 |

l2 + 2.8 |

l2 + 3.5 |

|

l2 |

15–100 |

15–100 |

15–100 |

20–100 |

25–100 |

|

a Length l1 applies to angle 140°only(without tolerance). |

|||||

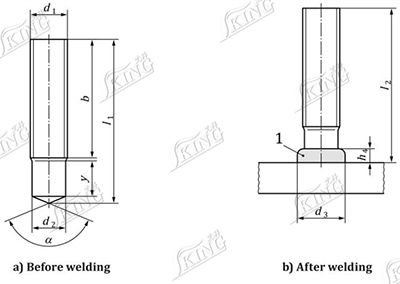

3. Partially threaded stud (PD)

|

d1 |

M6 |

M8 |

M10 |

M12 |

M16 |

M20 |

M24 |

|||||||

|

d2 ± 0.1 |

5.35 |

7.19 |

9.03 |

10.86 |

14.6 |

18.38 |

22.05 |

|||||||

|

d3ᵇ |

8.5 |

10 |

12.5 |

15.5 |

19.5 |

24.5 |

30 |

|||||||

|

h4ᵇ |

3.5 |

3.5 |

4 |

4.5 |

6 |

7 |

10 |

|||||||

|

α ± 7° |

140° |

|||||||||||||

|

l1 ± 1ᵃ |

l2 + 2.1 |

l2 + 2.2 |

l2 + 2.3 |

l2 + 2.8 |

l2 + 3.5 |

l2 + 3.8 |

l2 + 4.5 |

|||||||

|

l2 |

y+2P |

b |

y+2P |

b |

y+2P |

b |

y+2P |

b |

y+2P |

b |

y+2P |

b |

y+2P |

b |

|

15 |

9 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

20 |

9 |

- |

9 |

- |

9.5 |

- |

- |

- |

- |

- |

- |

- |

- |

- |

|

25 |

9 |

- |

9 |

- |

9.5 |

- |

11.5 |

- |

- |

- |

- |

- |

- |

- |

|

30 |

9 |

- |

9 |

- |

9.5 |

- |

11.5 |

- |

13.5 |

- |

- |

- |

- |

- |

|

35 |

- |

20 |

9 |

- |

9.5 |

- |

11.5 |

- |

13.5 |

- |

15.5 |

- |

- |

- |

|

40 |

- |

20 |

9 |

- |

9.5 |

- |

11.5 |

- |

13.5 |

- |

15.5 |

- |

- |

- |

|

45 |

- |

20 |

9 |

- |

9.5 |

- |

11.5 |

- |

13.5 |

- |

15.5 |

- |

- |

- |

|

50 |

- |

20 |

- |

40 |

- |

40 |

- |

40 |

13.5 |

- |

- |

35 |

20 |

- |

|

55 |

- |

20 |

- |

40 |

- |

40 |

- |

40 |

- |

40 |

- |

40 |

- |

- |

|

60 |

- |

20 |

- |

40 |

- |

40 |

- |

40 |

- |

40 |

- |

40 |

- |

- |

|

65 |

- |

- |

- |

40 |

- |

40 |

- |

40 |

- |

40 |

- |

40 |

- |

- |

|

70 |

- |

- |

- |

40 |

- |

40 |

- |

40 |

- |

50 |

- |

50 |

- |

50 |

|

80 |

- |

- |

- |

40 |

- |

40 |

- |

40 |

- |

50 |

- |

50 |

- |

50 |

|

100 |

- |

- |

- |

40 |

- |

40 |

- |

40 |

- |

80 |

- |

70 |

- |

70 |

|

140 |

- |

- |

- |

40 |

- |

80 |

- |

80 |

- |

80 |

- |

70 |

- |

70 |

|

150 |

- |

- |

- |

40 |

- |

80 |

- |

80 |

- |

80 |

- |

70 |

- |

100 |

|

160 |

- |

- |

- |

- |

- |

80 |

- |

80 |

- |

80 |

- |

70 |

- |

100 |

|

a Length l1 applies to angle 140°only(without tolerance). |

||||||||||||||

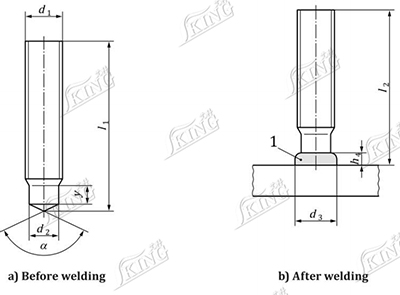

4.Threaded stud with reduced shaft (RD)

|

d1 |

M6 |

M8 |

M10 |

M12 |

M16 |

M20 |

M24 |

|

d2 ± 0.1 |

4.7 |

6.2 |

7.9 |

9.5 |

13.2 |

16.5 |

20 |

|

d3ᶜ |

7 |

9 |

11.5 |

13.5 |

18 |

23 |

28 |

|

h4ᶜ |

2.5 |

2.5 |

3 |

4 |

5 |

6 |

7 |

|

y + 2P |

4 |

4 |

5 |

6 |

7.5/11ᵃ |

9/13ᵃ |

12/15ᵃ |

|

α ± 7° |

140° |

||||||

|

l1 ± 1ᵇ |

l2 + 2.0 |

l2 + 2.2 |

l2 + 2.4 |

l2 + 2.8 |

l2 + 3.6 |

l2 + 3.9 |

l2 + 4.7 |

|

l2 |

15–100 |

15–100 |

15–100 |

20–100 |

25–100 |

30–100 |

40–100 |

|

The dimensions after the oblique stroke shall apply if ceramic ferrules. |

|||||||

5. Unthreaded stud (UD)

|

d1± 0.1 |

6 |

8 |

10 |

12 |

14.6 |

16 |

|

d3ᵇ |

8.5 |

11 |

13 |

16 |

18.5 |

21 |

|

h4ᵇ |

4 |

4 |

4 |

5 |

6 |

7 |

|

α ± 7° |

140 |

|||||

|

l1 ± 1ᵃ |

l2+2.4 |

l2+2.6 |

l2+2.8 |

l2+3.4 |

l2+3.9 |

l2+3.9 |

|

a Length l1 applies to angle 140°only(without tolerance). |

||||||

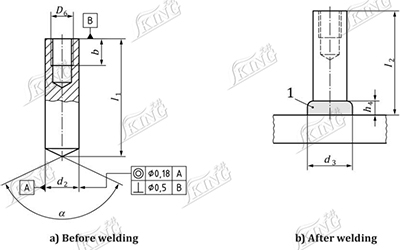

6.Stud with internal thread (ID)

|

D6 |

M5 |

M6 |

M8 |

M8 |

M10 |

M10 |

M12 |

|

d₂ ±0,1 |

10 |

10 |

12 |

14.6 |

14.6 |

16 |

18.38 |

|

d₃ᵇ |

13 |

13 |

16 |

18.5 |

18.5 |

21 |

23 |

|

b+2P |

7.5 |

9 |

12 |

15 |

15 |

15 |

18 |

|

h₄ᵇ |

4 |

4 |

5 |

6 |

6 |

7 |

7 |

|

l₂ min |

15 |

15 |

20 |

25 |

25 |

25 |

30 |

|

α ±7° |

140° |

||||||

|

l₁ ±1ᵃ |

l₂ min + 2,3 |

l₂ min + 2,3 |

l₂ min + 2,8 |

l₂ min + 3,5 |

l₂ min + 3,5 |

l₂ min + 3,5 |

l₂ min + 3,7 |

|

a Length l1 applies to angle 140°only(without tolerance). |

|||||||

Welding process

A. Stud is loaded into the weld tool and properly positionedagainst the base metal.

B. Trigger is depressed; Stud lifts, creating arc.

C. Arcing period completed and stud is plunged into moltenpool.

D. Weld is complete, weld tool is withdrawn andferrule removed for inspection.

Application

1. Construction Engineering: Shear connection between steel structure beams, columns, and concrete (e.g., high-rise stiffened columns).

2. Manufacturing: Sheet metal fixing for automobiles, home appliances, chassis, and pipe support anchoring.

3. Equipment Assembly: Prefabrication of threaded connection points for electrical cabinets and lifting machinery components.

Materials and mechanical characteristics offinished studs

|

Symbol |

Material/ material group/ property class |

Standard |

Mechanical properties of the finished stud |

|

FD |

4.8 |

IS0 898-1c |

See ISO 898-1 |

|

A2-50, A2-70,A4-50, |

ISO 3506-1c |

See ISO 3506-1 |